Wrinkled Intaglio Type

A plate making method where the ImagOn is pre-exposed to the image and crumpled or distorted in a number of ways before it is laminated to the plate.

ImagOn has great adhesive qualities in addition to its photo sensitive qualities

developed by Elizabeth Dove

Materials:

- ImagOn plate

|

Method

One:

|

|

|

| Olec Exposure Unit |

|

|

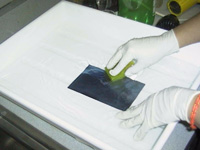

Rubber gloves RECOMMENDED for the development procedure. Repeated use of developing solution can dry out the skin and cause a dermatitis reaction on the hands. Eye protection advised. The developer is an alkaline solution. Do not splash the developing solution into eyes.

|

Develop

|

|

|

Dry Plate

|

Print Plate

|

|

.

.

.

.